Brechanlagen

Brechanlagen

Übersicht

Unser Programm an Backen-, Kegel- und Prallbrecher bietet unschlagbare Leistung und Mobilität für vielfältige Anwendungen.

Hauptvorteile

- Hervorragende Kornform

- Höchster Zerkleinerungsgrad

- Während des Brechens versetzbar

- Aufgabetrichter beschickbar durch Radlader und Bagger

- Kompakt und leicht zu transportieren

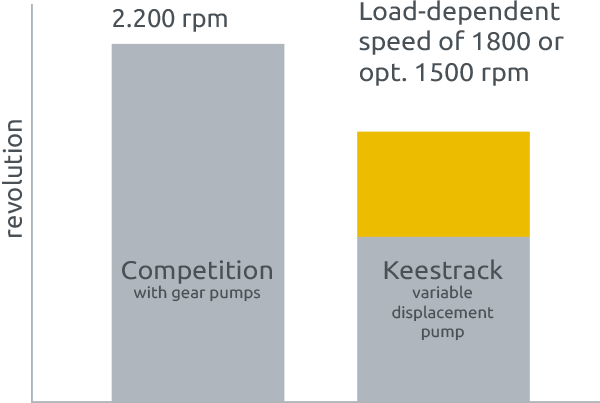

Erforderliche Motordrehzahlen bei maximaler Produktivität

B-Serie Backenbrecher

B-Serie Backenbrecher

R-Serie Prallbrecher

R-Serie Prallbrecher

H-Serie Kegelbrecher

H-Serie Kegelbrecher