Brekers

Aanbod brekers

Overzicht

Onze kaak-, kegel- en percussiebrekers bieden ongeëvenaarde prestaties en mobiliteit voor gebruik in uiteenlopende toepassingen.

Belangrijkste voordelen

- Superieure productvorm

- Hoogste verkleiningsfactor

- Machine kan verplaatst worden tijdens bedrijf

- Voedingsbunker geschikt voor wiellader en graafmachine

- Eenvoudig te vervoeren en compacte afmetingen

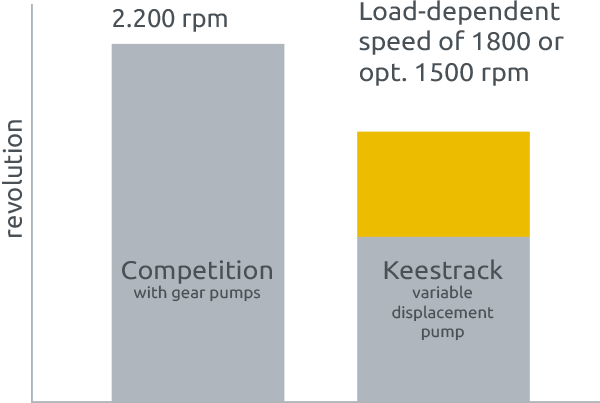

Vereist motortoerental voor maximale productiviteit

Kaak B Serie

Kaak B Serie

Percussie R Serie

Percussie R Serie

Kegel H Serie

Kegel H Serie