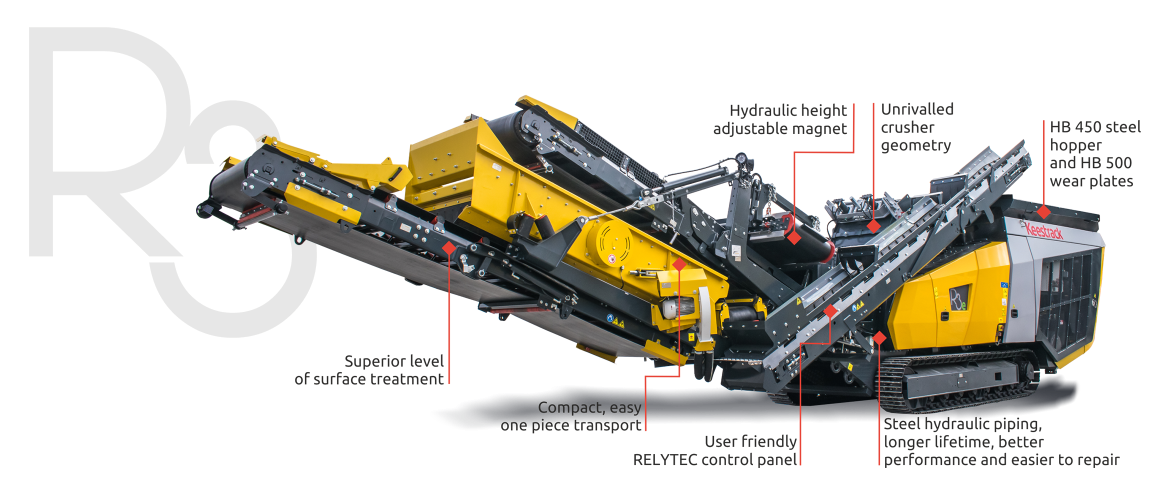

R3

Product information

Performance highlights

- Available in full hybrid e version

- Equipped in closed circuit < 30.000 kg, easy to transport without permit

- Hopper 3,5 m³ (4,5 yard³)

- Vibrating feeder with punched plate pre screen 1.200 mm x 920 mm (4’ x 3’)

- Due to integrated pre screen, higher crushing capacities and less wear

- Inlet opening (H x W) 770 x 960 mm (30” x 38’’)

- Superior rotor diameter 1.100 mm (44”)

- Optional 3rd impact panel as milling beam to produce high value end product

- Optional single deck after screen 3.100 x 1.400 mm (9’ x 4’)

- Optional double deck after screen 3.100 x 1.400 mm (9’ x 4’)

- Capacity up to 250 tonnes / hour

- Load sensing hydraulic system reduces fuel usage by 25%

- 2 speed track drive

- Highest reduction ratio

- Superior product shape

- Extensive option list to configure to your application

- Optional windsifter

Specifications

| Transport dimensions | Transport dimensions with after screen | Working length without after screen | Working length with after screen | |

|---|---|---|---|---|

| Weight | 27,5t (30 sT) | ± 32t - 33t (35 sT-36 sT) | ||

| Length | 10.000 mm (32’10”) | 12.900 mm (42’4”) - 13.260 mm (43'6") | 11.525 mm (37’10”) | 14.218 mm (46’8”) |

| Height | 3.200 mm (10’6”) | 3.200 mm (10’6”) | ||

| Width | 2.550 mm (8’4”) | 2.550 mm (8’4”) |

| Transport dimensions | Transport dimensions with after screen | |

|---|---|---|

| Weight | 27,5t (30 sT) | ± 32t - 33t (35 sT-36 sT) |

| Length | 10.000 mm (32’10”) | 12.900 mm (42’4”) - 13.260 mm (43'6") |

| Height | 3.200 mm (10’6”) | 3.200 mm (10’6”) |

| Width | 2.550 mm (8’4”) | 2.550 mm (8’4”) |

| Working length without after screen | Working length with after screen | |

|---|---|---|

| Length | 11.525 mm (37’10”) | 14.218 mm (46’8”) |

Fuel efficiency

Applications

- Limestone and many other low and medium abrasive natural rock

- Concrete and landfill recycling

- Primary and secondary crushing

- Yard clean up

- Construction waste

- Demolition waste

- Quarrying and mining

- Gravel

- Asphalt

- Coal and others