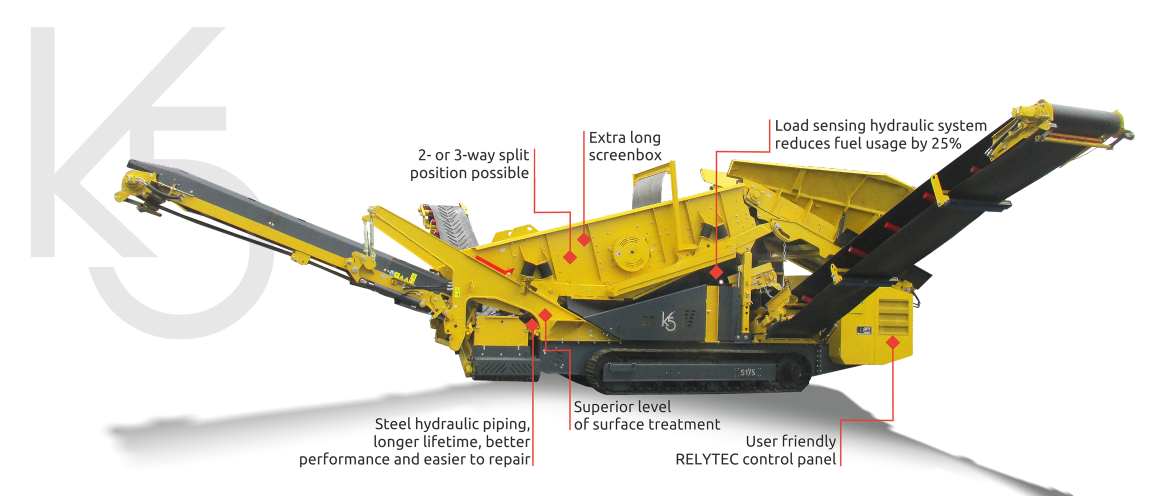

K5

Product information

Performance highlights

- Available in full hybrid version

- Standard heavy duty plate apron feeder and hydraulic folding hopper walls

- Double deck screen box 5.000 x 1.500 mm (17’ x 5’)

- 7,5 m² screening surface upper deck, 7 m² lower deck

- Capacity up to 450 tonnes / hour

- Contractor’s choice, compact by weight and dimensions

- Optional Double deck Bivitec FLIP FLOW screen box 5.000 x 1.350 mm (17’ x 4,5’)

- Screening force up to 40 G

- 6,75 m² screening surface upper deck, 5,4 m² lower deck

- Feed hopper 7 m³ (9 yard³), several hopper extensions available

- Low emission engine

- Lowest fuel consumption in the industry

- Large range of screen meshes, fingers, punched plate & grizzly decks available

- Hydraulical liftable screenbox

- Hydraulic adjustabe screen angle

- 2 speed track drive

- Extensive option list to configure to your application

Specifications

| Transport dimensions | Working dimensions | |

|---|---|---|

| Weight | 28,5 t (31 sT) | |

| Length | 11.296 mm (37’1”) | 14.450 mm (47’5”) |

| Height | 3.330 mm (10’11”) | 4.380 mm (14’4”) |

| Width | 2.550 mm (8’4”) | 14.010 mm (46’) |

| Transport dimensions | Working dimensions | |

|---|---|---|

| Weight | 28,5 t (31 sT) | |

| Length | 11.296 mm (37’1”) | 14.450 mm (47’5”) |

| Height | 3.330 mm (10’11”) | 4.380 mm (14’4”) |

| Width | 2.550 mm (8’4”) | 14.010 mm (46’) |

Fuel efficiency

Applications

- Pre- screening/scalping

- Recycling landfill and construction waste

- Top soil and many other products

- Separation of “sticky” aggregate

- Construction and demolition waste

- Screening behind or before a crusher

- Sand and gravel

- Quarrying and mining

- Coal

- Wood and others