Crushers

Crusher range

Overview

Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications.

Key benefits

- Superior product shape

- Highest reduction ratio

- Ability to track while producing

- Intake hopper suitable for wheel loader and excavator

- Easy to transport and compact dimensions

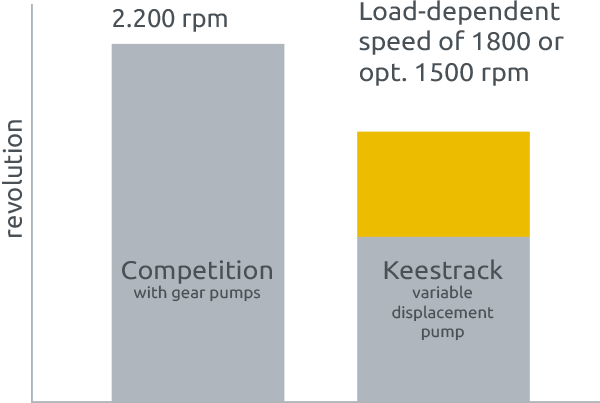

Engine speed required to achieve maximum productivity

Jaw B Series

Jaw B Series

Reversible Impact I Series

Reversible Impact I Series

Impact R Series

Impact R Series

Cone H Series

Cone H Series