Successful INTERMAT for Keestrack

Hightech on the catwalk

Displaying an award-winning attractive world premiere on the stand, information about numerous new models presented in the last months and a new structure of their French dealer and service network – these were the highlights of Keestrack’s Intermat presentation. “The show results exceed by far our expectations,” declares Kees Hoogendorn, President of the Keestrack Group. “Experts throughout all relevant sectors were interested in our processing technologies. Enquiries did mainly focus on our crushing solutions and here in particular on our modern hybrid and full hybrid drive concepts.”

Attractive new line

Beside a Keestrack dust suppression canon and several original crushing tools and wear parts the new track-mounted impact crusher Keestrack R3e was the real “show-stopper” on the stand of the international mineral processing specialists. Having been awarded as “Red Dot Winner” for outstanding industry design shortly before the show, the modern lines also impressed the Intermat visitors.

Under the extensive composite/steel cover of the compact 250-tph crusher, it was the innovative implementation of the full hybrid diesel-electric drive concept with 235 kW Volvo EU-IV diesel engine, 300-kVA generator and two separate electric motors for the crusher drive (opt. 132 kW/160 kW) and for the supply of the whole plant hydraulics (45 kW) to convince all experts. This enables the Keestrack R3e to work fully autonomous in diesel-electric mode, but also fully electric when connected through the standard “plug-in”-function to mains or an external gen set. Even then, repositioning of the machine or adjusting the conveyors is possible without starting the diesel engine. In all operating modes a 63 kVA “plug-out” connection supplies connected electric screeners or stackers, which allows for example an emission-free operation of inner-urban recycling machine combinations for defined end products.

The Keestrack R3e offers high flexibility and mobility: With a large inlet opening of 770 x 960 mm the impact crusher unit 48 ICR 100-00 features a heavy 920-mm rotor ((Ø: 1100 mm, 3200 kg) operating at high speed. Changeable belt pulleys at the electric crusher motor allow adjusting the crushing characteristics additionally. Specially adapted crushing tools, a wide adjustment range for both impact aprons (milling beam is optional) and a sophisticated overload system safeguard a broad range of applications from concrete recycling with intensive wear to the production of high-quality mineral aggregates.

With approx. 32 tonnes, the full electric Keestrack R3e weighs fully equipped barely 1000 kg more than the also available conventional diesel-hydraulic version. The full equipment includes: vibrating pre-screen with optional fines conveyor, overband magnet at the main conveyor and the new optional single deck after screen unit (4,4 m²) with recycling conveyor including optional wind sifting or a removable side conveyor for stockpiling the oversize as second end product.

„After three years of development, the Keestrack R3e is the machine which combines all key features of our hybrid technology. It perfectly applies to customer needs for compact high-performance crushers and reflects in an almost spectacular way our design philosophy, optimized in terms of safety and ease of operation,” summarizes Kees Hoogendoorn the positive customer reactions at the premiere. “We received many enquiries, including very specific projects, on which we also discussed other solutions from our comprehensive range of crushing technologies. I am confident, that following up the leads, our international sales partners will generate numerous orders also at new Keestrack customers.”

A new set-up in France

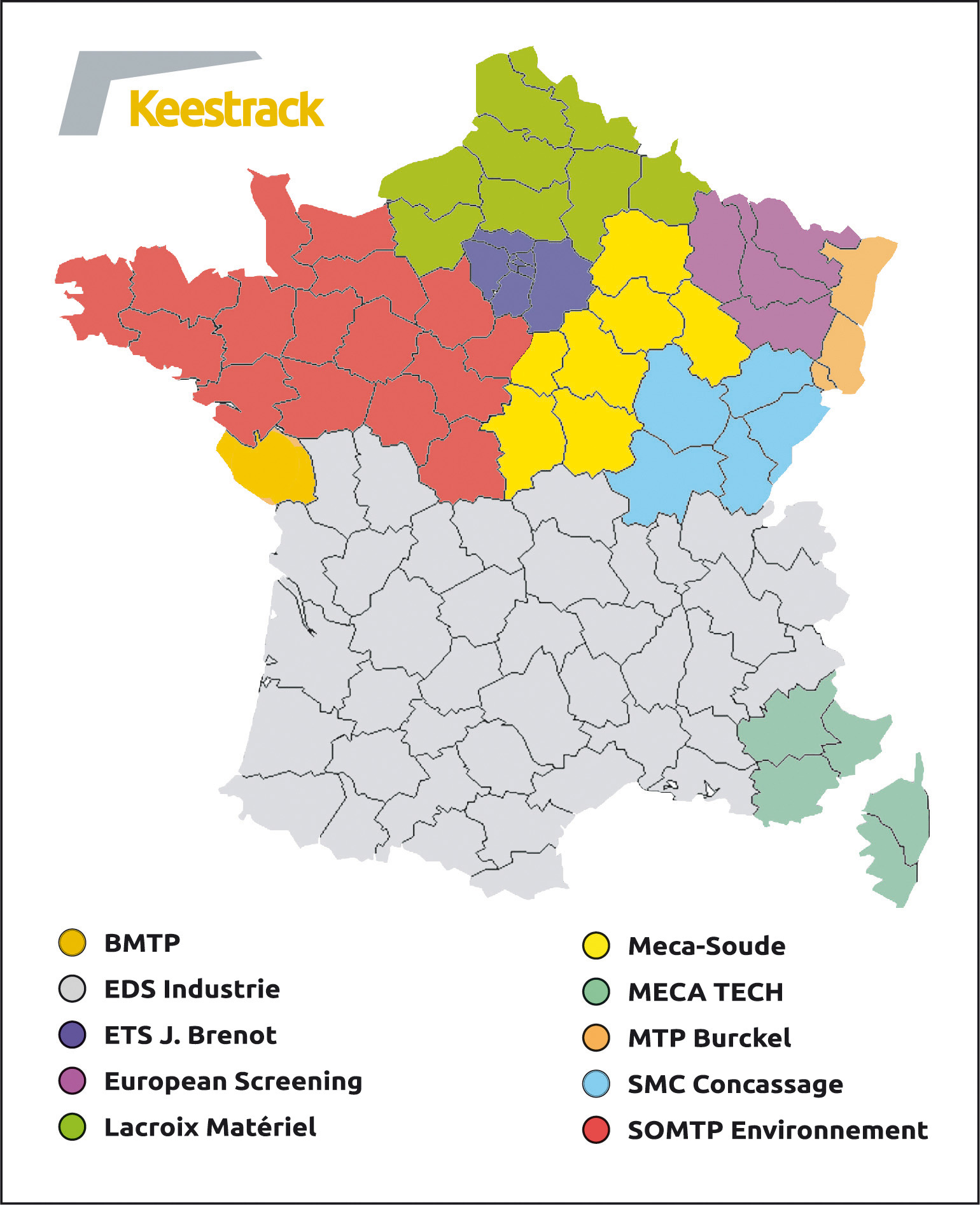

The importance of an extensive and dense sales and service network on national markets was proven at the French home match at Intermat. During the last months Keestrack substantially restructured its French distributorship and service organisation, now ten dealers and service partners cover all regions. “Processing technology was weakly represented on this year’s Intermat, but we experienced a great attendance of French experts from the quarrying and recycling sectors. Our increased activities are really paying off, and France, as one of the important European markets, shows significant signs for an economic upswing,” Kees Hoogendoorn concludes.